Tailored Molds & Optics

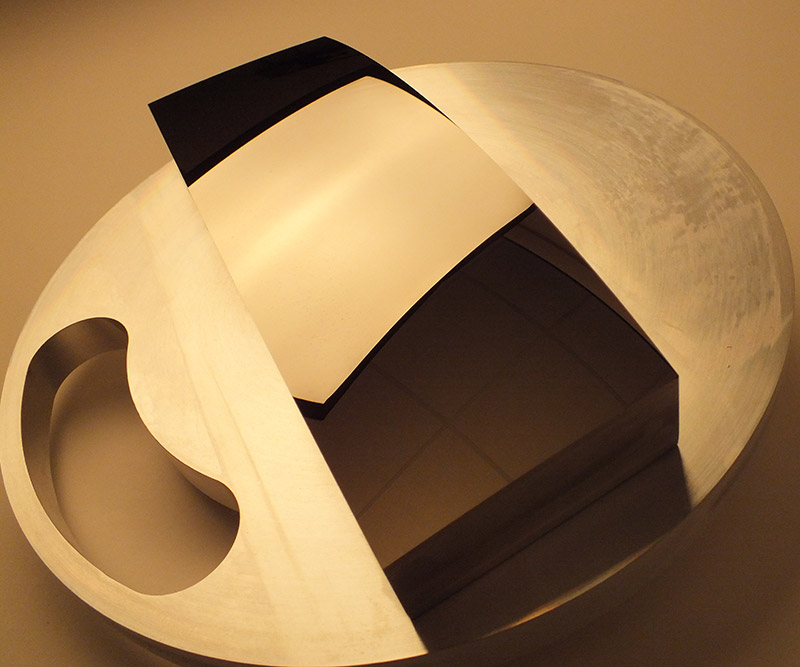

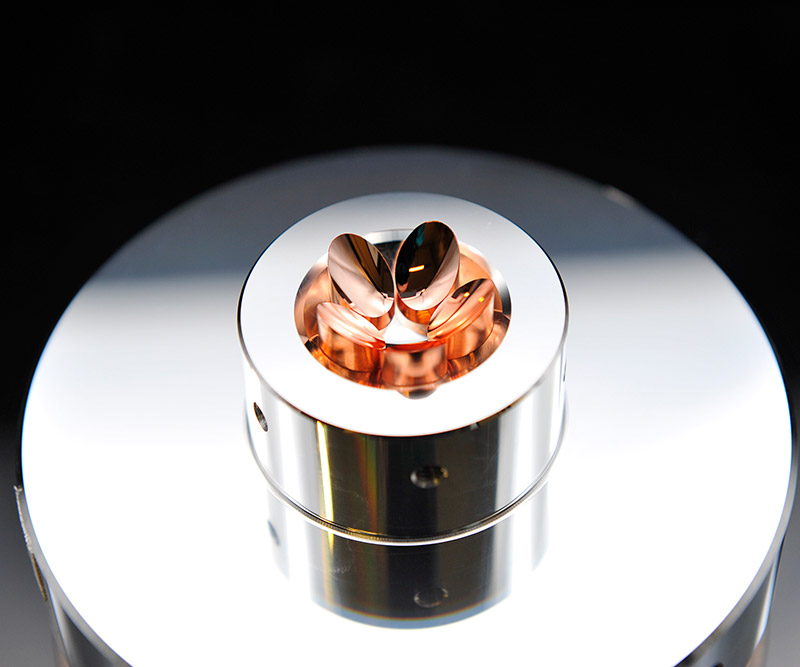

Spheres & Aspheres

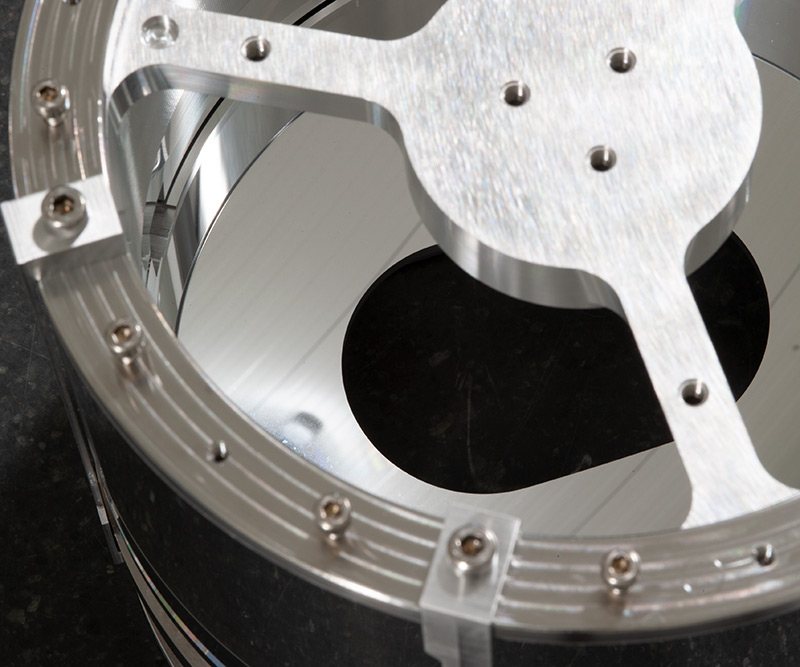

Flats

Free-Form Shapes

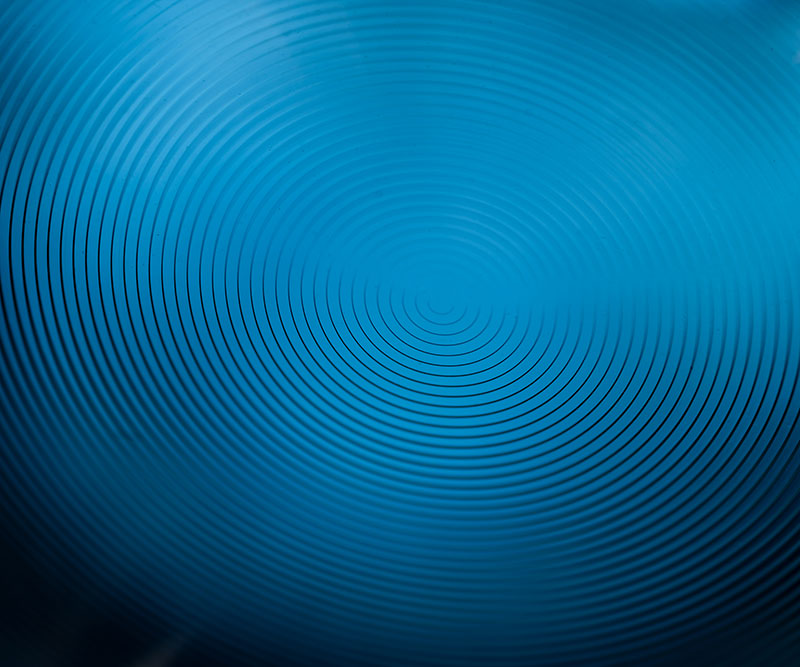

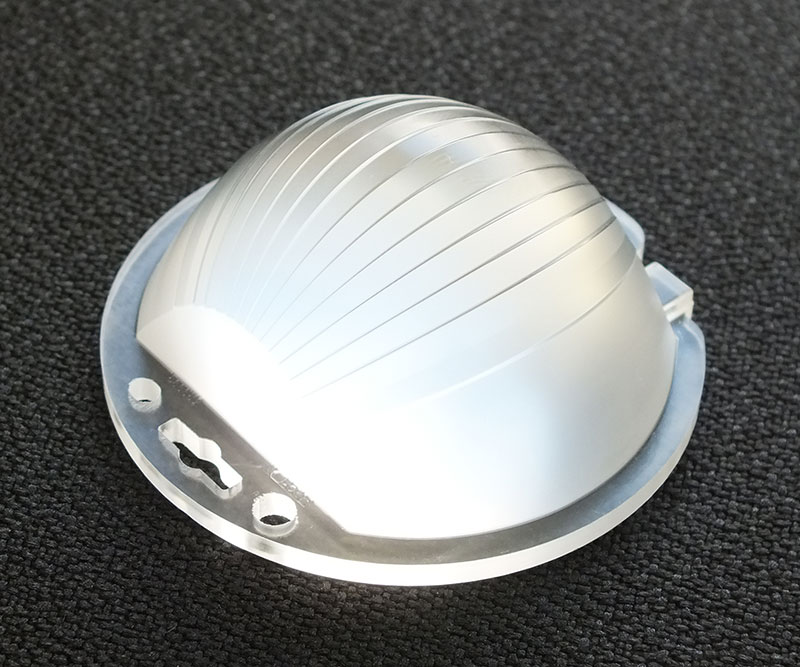

Fresnels

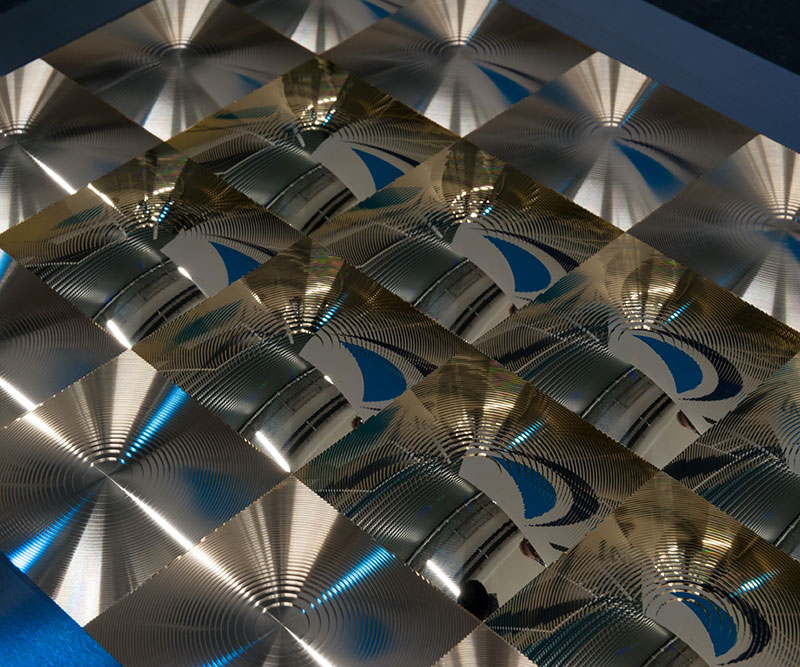

Lens Arrays

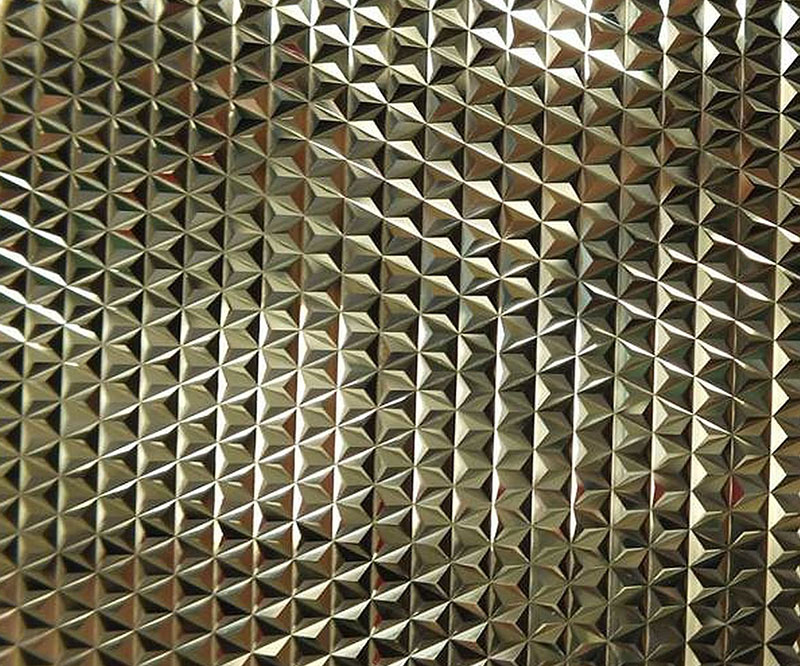

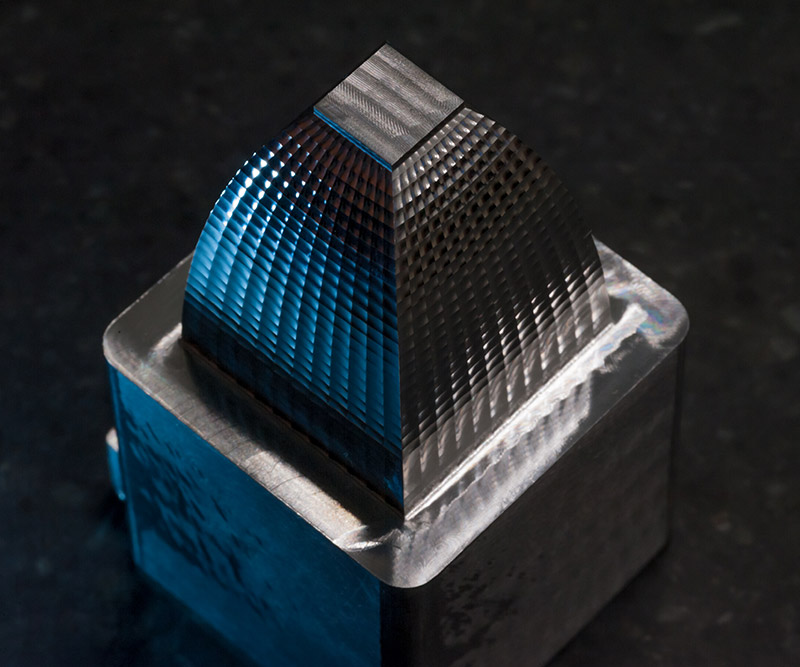

Micro-Structures

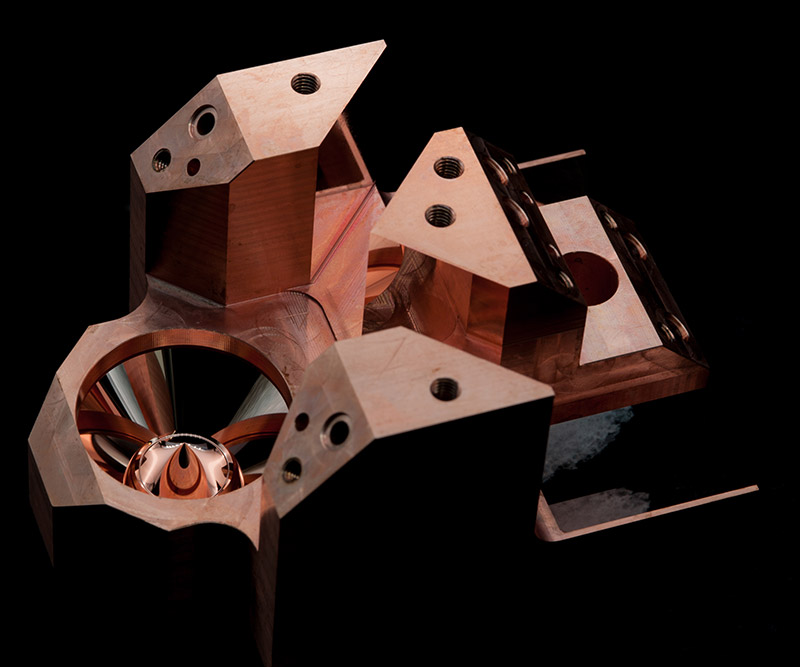

Prisms

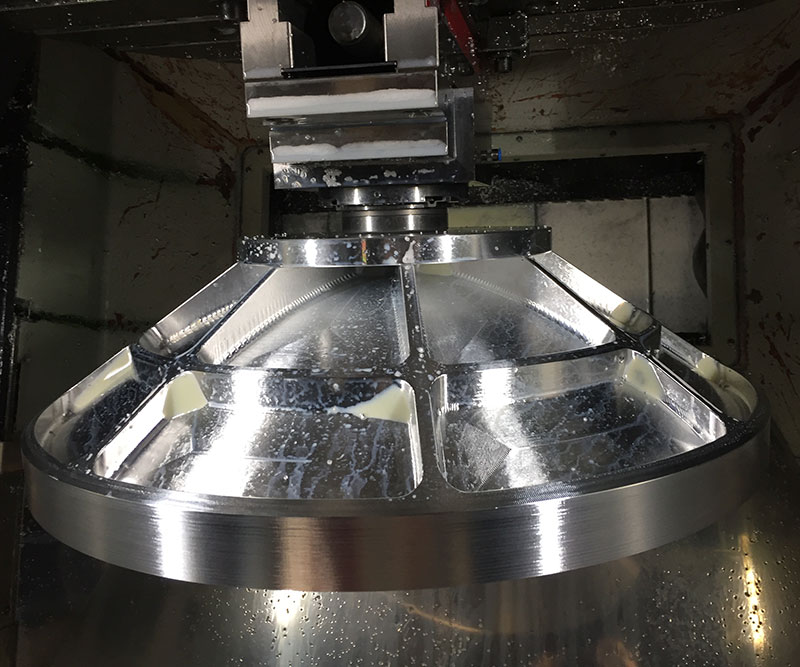

Large-Scale Optics

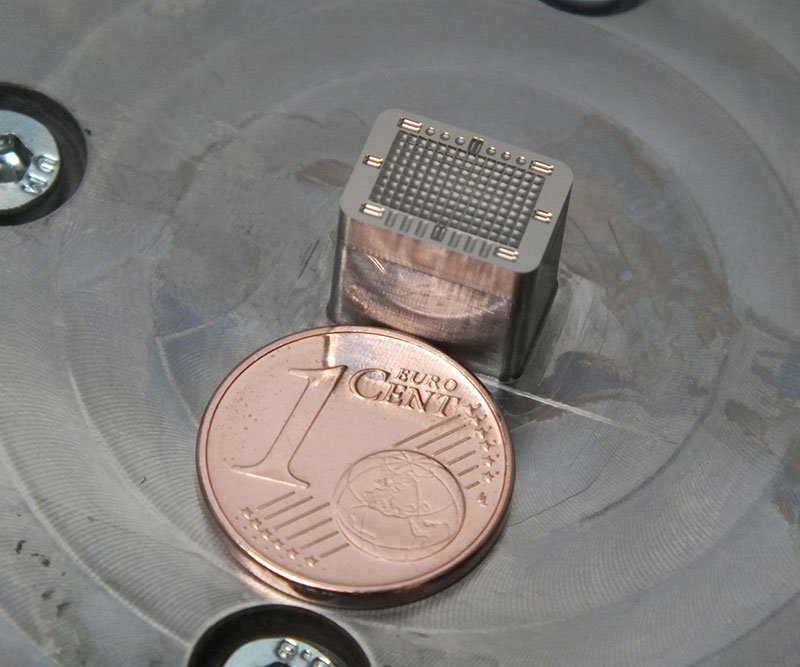

Micro-Optics

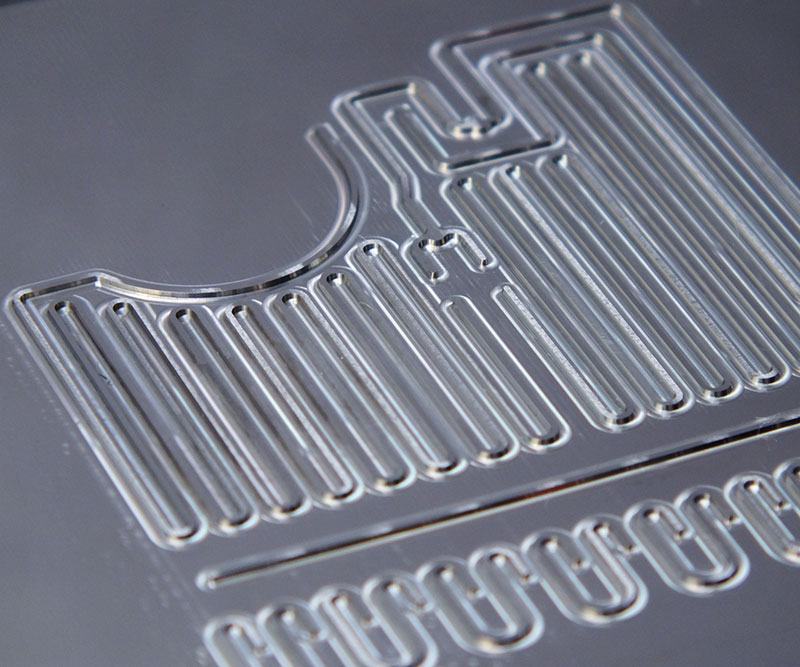

Micro Fluidics

Paraboloids & Off Axis

Assemblies & Systems

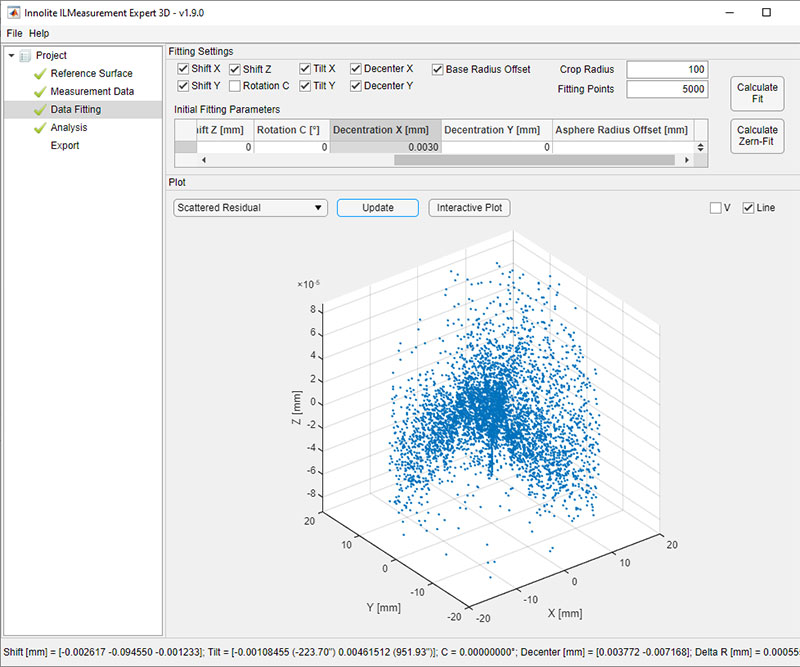

Data Analysis & Processing

Pre-Machining

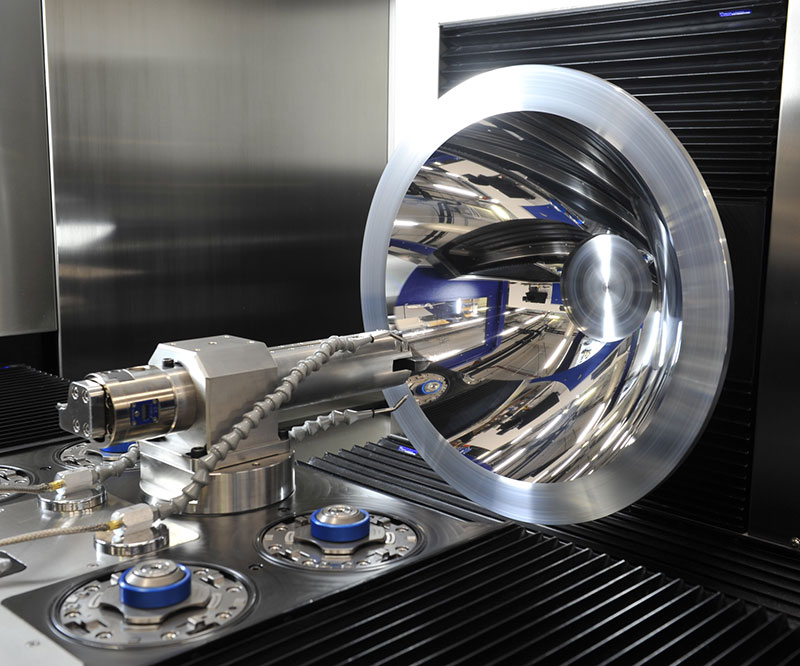

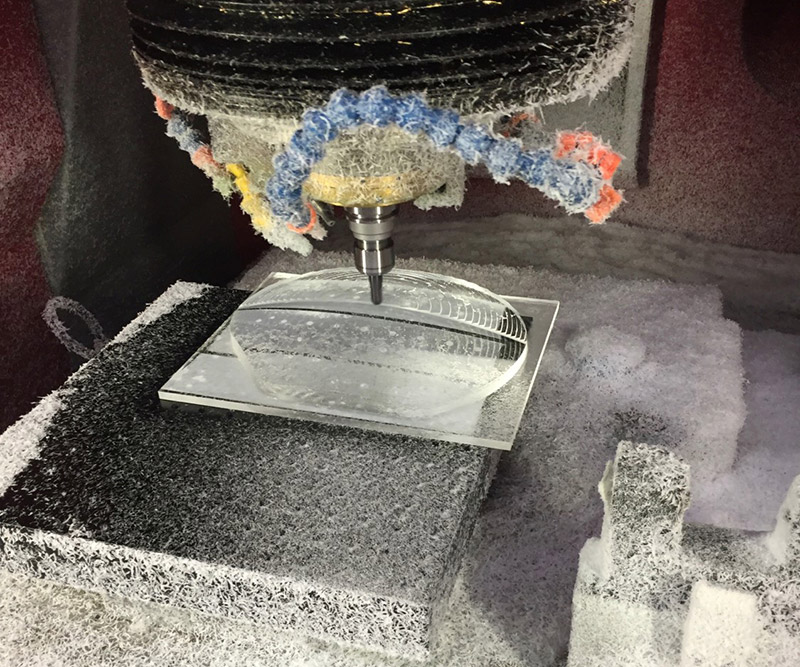

High Precision Milling

Ultra-Precision Machining

NiP Galvanic Coating

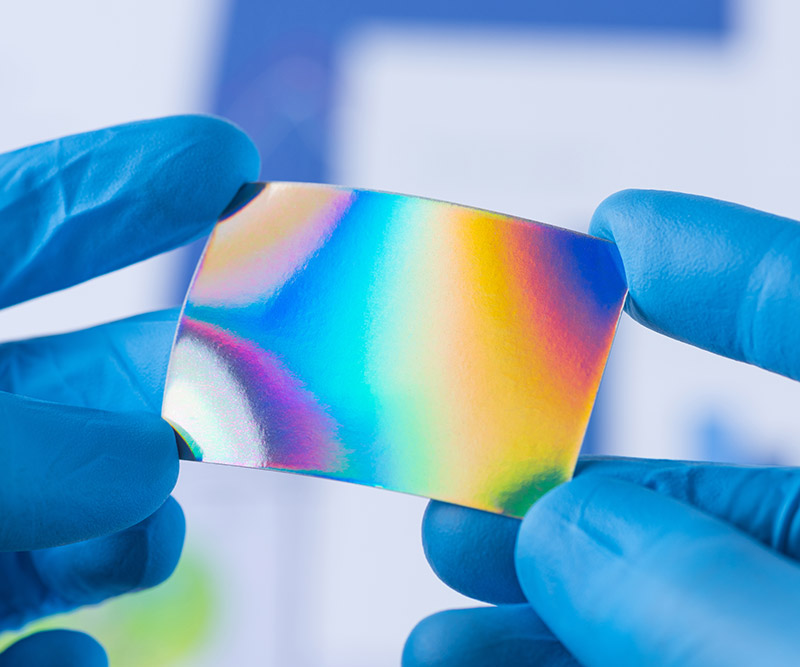

Optics Coating

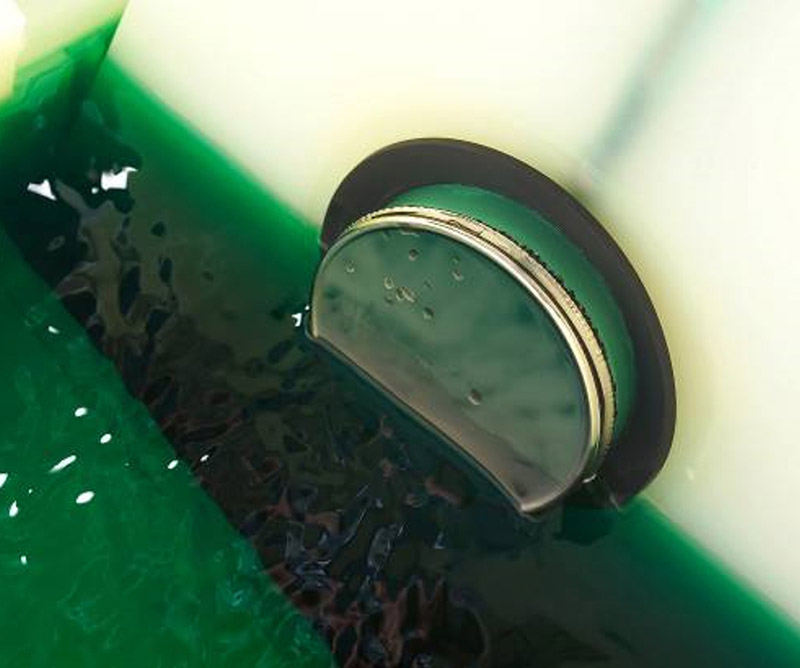

Injection Molding & Replication

Characterization

Automotive

LED Headlights, Head Up Display, Rain Sensor, Back Lights, Interior Illumination

Aviation

Head Up Displays

Ophthalmic

Contact Lenses, Eye Glasses

AR/

VR Smart Glasses

VR Smart Glasses

Direct Projection, Light Guide Based

Energy

Fresnel Collectors for Concentrating Photovoltaics

Medical

Projection Optics in Diagnostics

Architectural Illumination

Free Form Optics for Tailored Intesity Distribution

Luxury Goods

Image Projection, Watches

Industrial Laser Processing

CO2 Mirrors, Free Form Mirrors for Intensity Tayloring

Space & Aviation

Mirrors for Laser Measurement

Metrology

Gratings for Spectroscopy